Published 6 August 2019 ● Last Updated on 17 July 2020

“Consumer is king” has been the dominant thought in innovation circles in recent times. Unfortunately, in the last 2 decades or so, this has meant that markets have been flooded with conveniences for the consumer – much of it having an adverse impact on our planet. However, as consumers today become more conscious of what they buy and the cost to our environment, one can see that big brands are also changing their products and processes to become more environment-friendly.

Top companies and brands are working on their ‘green’ quotient, starting from inside the office to the outside structure, from corporate buildings to factory sheds, from transparent supply chains to better processes, and finally products and packaging.

Clearly, some of these Ps hold promise and in this article we look at some of these eco friendly ‘P’ innovations (Product, Process and Packaging) that big brands are applying to become more sustainable.

Product Innovation

Recycled Plastic Shoes by Adidas Parley │ What’s special about these sports shoes? Well, they are made using recycled plastic that has been collected from our oceans!

Adidas partnered with Parley for the Oceans – an organisation that works on protecting our oceans, to create this unique collection. Plastic trash that is collected from beaches and coastal communities is converted into polyester yarn which is used to create these shoes.

In 2016, Adidas UltraBoost was the first shoe model to be made using this recycled plastic yarn – each shoe needing recycled yarn made from 11 plastic bottles. Since then, Adidas production has kept on increasing as there is a demand for these eco friendly shoes. In their press release in January 2019, the company shared their goal , “… After one million pairs of shoes produced in 2017, five million in 2018, we plan to produce eleven million pairs of shoes containing recycled ocean plastic in 2019.” Imagine the number of bottles that are going to be used for a better cause instead of just bobbing up and down in the ocean forever!

Adidas is also using this yarn to create other sports apparel like jerseys, swimwear, backpacks and more.

The best part about this innovation is that many other shoe brands have also made the shift to recycled plastic yarn like Nike, Timberland, Rothy’s and Vivobarefoot to name a few.

Bio-Plastic Blocks from Lego │ These trees, bushes and leaves tell a story… a story about Lego’s commitment to going green by 2030 by ensuring the use of sustainable materials in their products and packaging.

Starting 2018, Lego boxes included the first eco friendly pieces – leaves, bushes and trees that were made using bio-plastic. These elements are made from polyethylene – a soft, durable and flexible plastic that is made using ethanol extracted from sugar cane material instead of using ethylene and propylene that come from polymerisation of fossil fuels. However, the production method of both plastics is very similar and while bio plastics can be recycled multiple times, it is not 100% biodegradable.

Earlier, the Danish company invested around $149 million to build a Sustainable Materials Centre to help research and eventually produce a more eco friendly product. Lego has also partnered with WWF to ensure that the raw material (sugarcane) that is being sourced for their bioplastic meets global standards of sustainable production.

While these new elements are only 1 – 2% of Lego’s total production; as Tim Brooks (VP – Environmental Responsibility at The Lego Group) said, “This is a great first step in our ambitious commitment of making all LEGO bricks using sustainable materials.”

Piñatex Sustainable Leather │ Made using pineapple leaves fibre, this leather is natural, sustainably sourced and cruelty free. Plus it is an added income for the community as the leaves are usually discarded as waste when the pineapple fruit is harvested.

Ananas Anam Ltd., the company that produces Piñatex, was founded by Dr. Carmen Hijosa. A consultant in the leather industry, Carmen visited the Philippines in the 1990s and was shocked to see the negative impact that the industry had both on the environment as well as the workers. From there on began her journey to find a more sustainable alternative to leather and more that 7 years of research and development led to her creating Piñatex.

Unlike traditional ‘animal’ leather which pollutes nearby water bodies and toxic fumes released add to air pollution, pineapple leather is produced in an eco friendly way. The long fibres from the leaves are extracted, degummed and then undergo an industrial process to form a non-woven mesh. These are then sent to Spain for finishing that gives them the leather look. The finished textile is directly distributed to designers who use it as an alternative to leather to make shoes, hand bags, fashion accessories and even airplane and car seat covers!

Process Innovation

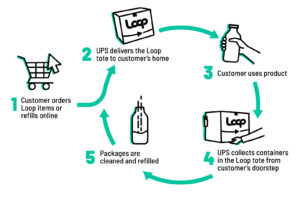

Reusable Packaging by Loop│ Never thought I’d say this, but some ‘plastic loops’ are beneficial for our environment! The company Loop aims to move from the traditional plastic linear economy (use and throw) to a more circular plastic economy (recycle and reuse).

This initiative by TerraCycle was announced at WEF Annual Meeting in Davos in January of 2019. Then the pilot projects of the Loop system were put into action in two markets – Ile-de-France region and New York Region in US. Many big brands like Procter & Gamble, PepsiCo, Unilever, Nestle, Coca-Cola, Danone and more have signed up to be a part of this initiative.

What is the Loop? You buy your products online through the Loop store or on any retail partners’ website. You pay a small deposit for the reusable containers (it is refunded once the container is collected!) The products are sent to you in a special bag in which you put the empty containers back and return using a courier services so that the containers can be processed and refilled. This way millions of product bottles and packaging will be saved from ending up in our trash.

While most of it is online now, if the concept catches on Loop plans to have stores where customers could come and refill their products in reusable containers or simply drop them off for recycling.

Reinventing Trash by Miniwiz│ We call it trash and discard it; Miniwiz looks at it as an abundant resource that can be upcycled into something more. And that is exactly what the company is doing at its TRASHLAB – experimenting with trash to create something useful. Their range of innovations have grabbed not just our attention, but of others ranging from Nat Geo to Jackie Chan to the Singapore government!

Founded in 2005 by Arthur Huan and Jarvis Liu, the company has been working on many path breaking projects to put trash to good use by creating new materials out of them, just over 1200 sustainable materials for now. They have also developed Robin, an AI smart recycling system that gives you points in return for your recyclable trash and you can use those points to shop for Miniwiz products. TRASHPRESSO, another of their creations, is a solid waste recycling line that recycles in 3 steps – size reduction, purification and shaping and currently can upcycle 50 kg of plastic waste an hour to convert them into tiles!

In 2015, WEF recognised Miniwiz as a technology pioneer highlighting the positive impact the company’s work has had on the environment and economic development. Take a look at all the projects undertaken by Miniwiz here; a clear indication that trash has more potential than we ever imagined.

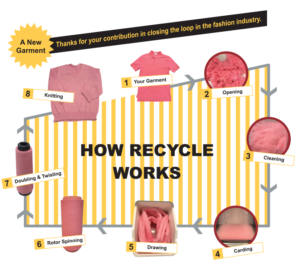

Clothes Recycled by HKRITA│ If you could wish for new clothes in an eco friendly way, let us introduce you to your genie the Garment-to-Garment recycle system (G2G). The G2G is mini production unit that recycles your old clothes into new ones – from cleaning it to taking out the fibre to making it into new yarn and knitting a new garment. A one-stop solution to our fashion waste from entering our landfills.

Developed by Hong Kong Research Institute of Textiles and Apparel (HKRITA), G2G – A Mini Mill within the Mills won the Product Design Red Dot Award 2019. The concept behind the project was to allow people to see how old clothes are recycled into new so they get a better understanding of the process as well as want to experience it themselves by recycling their old clothes. The entire setup is in a 40 foot glass walled container that is soundproof and anti vibration allowing for it to be set up in any commercial area. Currently, there is one setup of G2G at The Mills in Hong Kong.

The G2G system is a part of a much larger project by HKRITA that has been funded by H&M Foundation, as the fashion retail brand hopes to be using sustainable materials for all its garments by 2030. A recycling plant has been set up in Hong Kong to use the hydrothermal recycling technology – using heat, water and a mix of biodegradable chemicals to separate cotton and polyester from mixed fabrics so that they can be reused. H&M has invested € 5.8 million in this 4 year collaboration (2016 to 2020) with HKRITA to work on various research projects to help the fashion retail brand achieve its sustainability goal.

Packaging Innovation

Biodegradable Packaging for Ikea│ The ‘mushroom’ may solve our mushrooming plastic packaging waste crisis! EcoCradle is a biodegradable packaging material made out of agricultural waste and mycelium, the part of a fungus that grows roots and branches. The process to make this packaging is simple – bio materials are compressed into a desired shape and mycelium is used as natural glue, it binds the shape with the roots that it grows. Finally the material is heat treated to stop the fungus from growing further and then used for packaging. The best part about this packing is that it is biodegradable and is expected to decompose in 60 to 90 days.

US-based, Ecovative Designs is responsible for this sustainability innovation that will change the way the packaging industry works and will hugely reduce the plastic waste that is generated.

Ikea, the Swedish multinational company, has announced that it will replace all its styrofoam packaging with EcoCradle. Ikea has been the world’s largest furniture retailer since 2008, so this shift to biodegradable packaging will surely help. Brands like Dell and others have already made the shift to this mushroom based packaging material.

No Packaging for Lush│ Being naked is most sustainable and Lush products do it like no one else.

Lush launched their first ‘naked shops’ in Milan and Berlin in 2018 and in Manchester in 2019. And so far, the customers are quite intrigued by the ‘naked’ in the concept but open to the no packaged product idea. Further to help customers know more about the products as there is no packaging on them, the Lush R&D team have created the Lush Labs App with a feature called Lush Lens that allows the customers to see all the info they need about the product by simply taking a photograph of it!

When it comes to reduced packaging, Lush is quite a pioneer in this area. Take a look at these 10 things about Lush Packaging.

Conclusion

All the sustainability innovations hold promise and we hope there will be more brands and companies that will work towards becoming more environmentally friendly.

Related Articles

Eco Brands│ How JUNK NOT! is turning trash to treasures, one plastic piece at a time!

0 Comments